Chemical resistance material coupons are available for final determination of chemical resistance.

Vinyl ester resin chemical resistance chart.

Resin technologies 70.

Negligible effect on mechanical properties.

They offer high resistance to solvents acids and oxidizing substances such as chlorine.

Selecting a resin for the structural wall 69.

Vinyl ester standard vinyl ester resins offer excellent resistance to acids alkalis and oxidizing.

Derakane 510n resin is brominated epoxy novolac vinyl ester resin that offers a high degree of fire retardance1.

They also offer high retention of strength and toughness at elevated.

They are very resistant to chemical attack by chlorine and bleach environments.

Epoxy novolac vinyl ester group 72.

Mechanical forces 69.

Vinyl esters have enhanced mechanical properties compared to polyesters with physical strength better impact and thermal shock resistance.

Vinyl ester group 71.

A no attack possibly slight absorption.

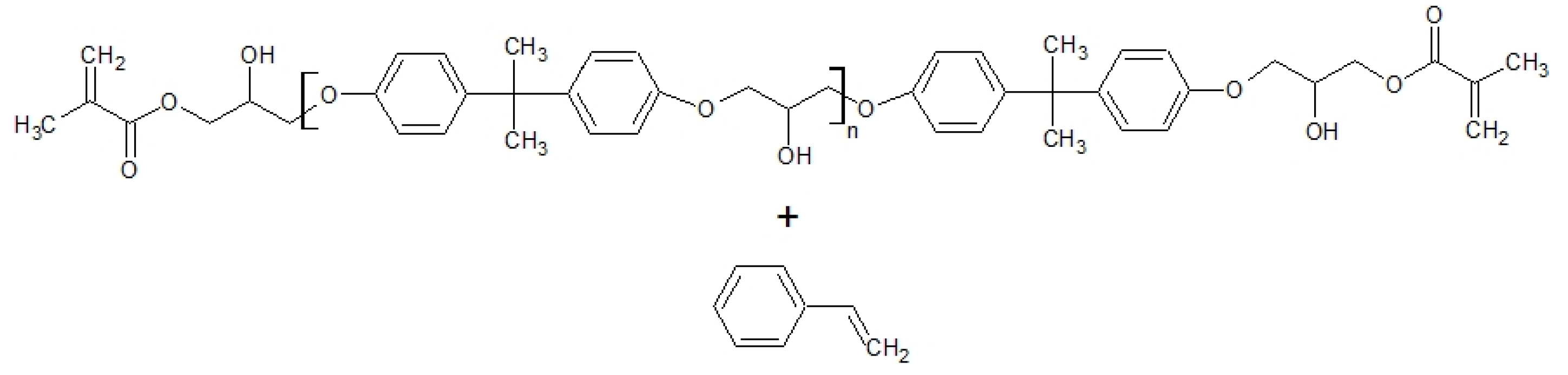

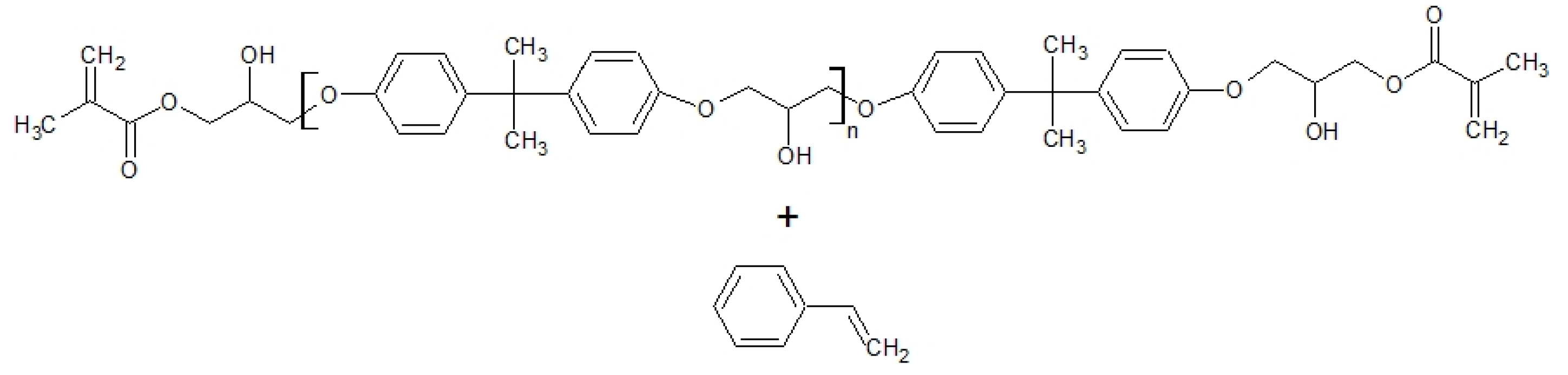

Vinyl ester or vinylester is a resin produced by the esterification of epoxy resin with unsaturated monocarboxylic acid.

Equipment requiring superior corrosion resistance and thermal properties to standard flame retardant epoxy vinyl ester resins.

Rubber modified vinyl ester group 72.

Class i astm e84 without antimony additives.

It is the most resistant resin in our portfolio against chlorine bleach and hot wet flue gas environments.

Selecting a resin for the corrosion barrier 68.

Improved resistance to hydrocarbon solvents and oxidizing media.

Derakane and derakane momentum 510a c resins are brominated epoxy vinyl ester resins that offer a high degree of fire retardance1.

Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid.

Derakane 470 series resins are epoxy novolac based vinyl ester resins designed to provide exceptional thermal and chemical resistance properties.

Hetron fr998 35 flame retardant epoxy vinyl ester resin.

In assessing a resin for a particular environment factors other than maximum.

Flame retardance 69.

Process temperature 68.

Some swelling and a small reduction in mechanical likely.

In the chart please contact aco.

Their bromine content makes them tougher and more fatigue resistant than standard epoxy vinyl ester resins.

Epoxy chemical resistance chemical resistance of epoxy to common products as acetic acid alcohol diesel oil and more fiberglass pipes and temperature limits temperature ranges for fiberglass epoxy furan phenolic polyester and vinyl ester pipes.

Vinyl esters also use peroxides e g.

Derakane 8084 resin is an elastomer modified bisphenol a epoxy vinyl ester resin that offers very high toughness impact and.