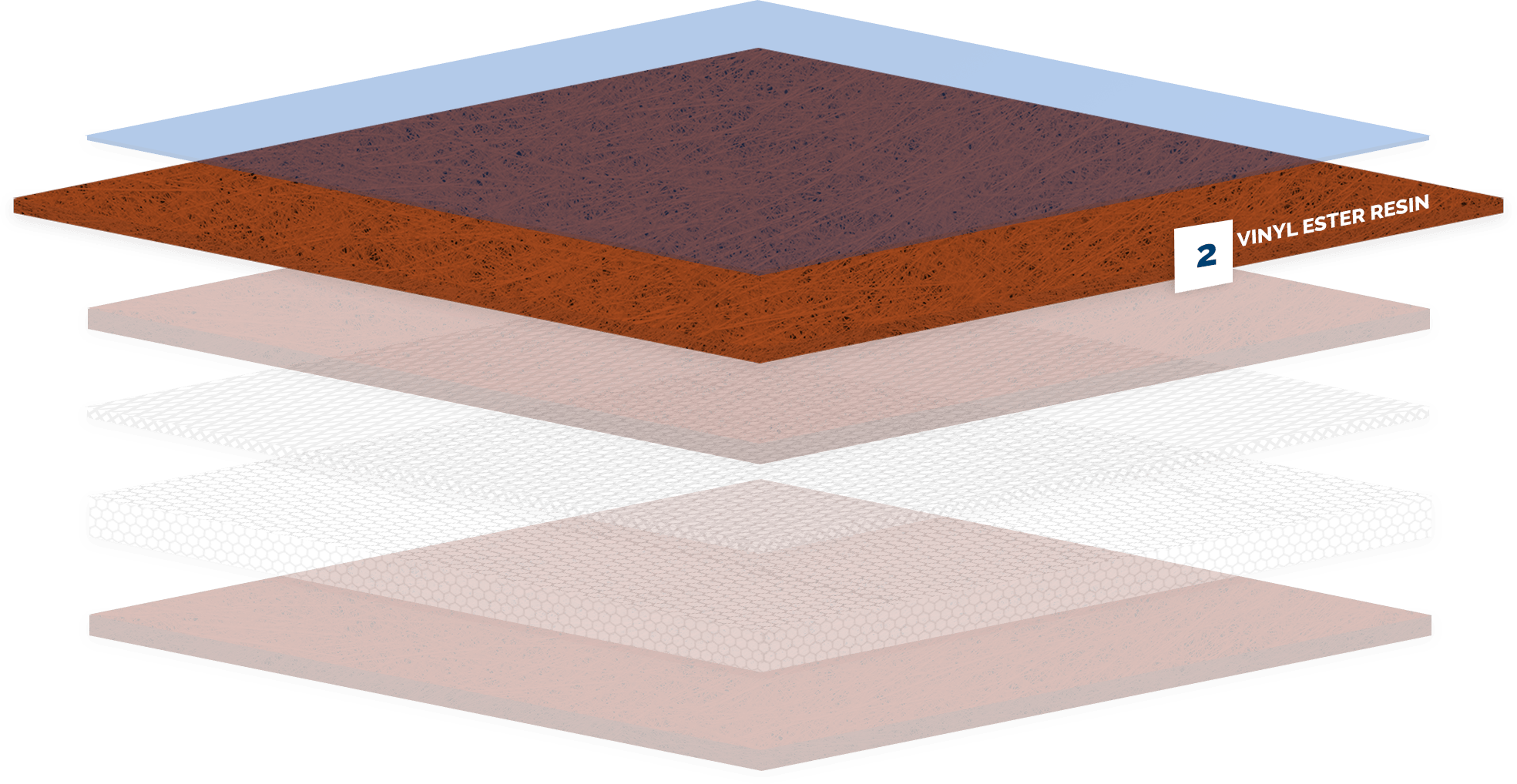

Utilizing vinyl ester resin with our fiberglass basins we can assist with engineering a specific tank for your chemical resistant and high temperature applications topp has experienced individuals on staff to help determine your vinyl ester needs or help design a complete.

Vinyl ester resin temperature resistance.

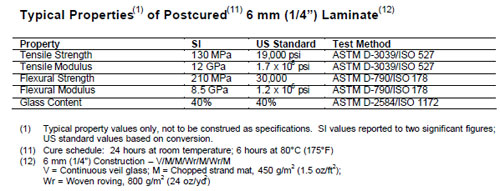

It also exhibits excellent solvent and acid resistance as well as high flexural strength and heat resistance.

It is also useful in hot wet fluegas environments where.

It exhibits a corrosion resistance similar to derakane 470 resins in most environments.

The topp premium series made with vinyl ester resin is engineered to tolerate high temperature and is corrosion resistant.

Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain.

It is important to note that of the three vinyl ester resin will provide the highest corrosion resistance temperature resistance and elongation toughness.

Candidates are designed for extremely high heat resistance rang ing from very high cross link density to toughened.

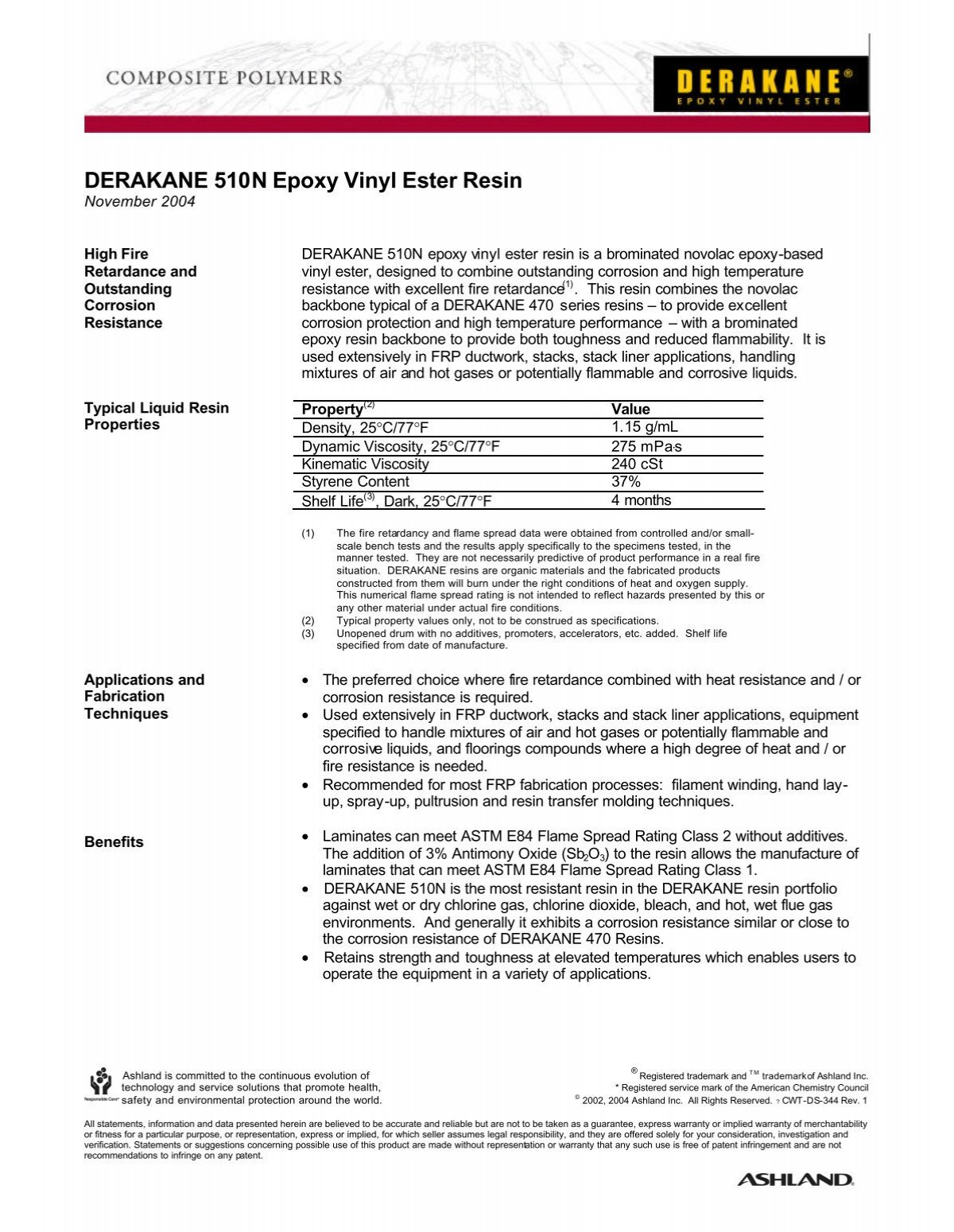

Derakane 510n resin is brominated epoxy novolac vinyl ester resin that offers a moderate degree of fire retardance1.

Vinyl ester resin is considered a hybrid of polyester and epoxy meaning its handling characteristics properties and price generally fall just between the other two.

Temperature compared to derakane 451 400 resin.

Vinyl esters have enhanced mechanical properties compared to polyesters with physical strength better impact and thermal shock resistance.

It has a measured glass transition temperature t g of 110 c hence allowing the clamp to withstand up to a maximum service temperature of 80 c.

Mirteq australia pty limited is a privately owned australian company that manufactures a range of concrete and steel paint coatings for australian conditions.

Perature resistant vinyl ester has been developed with a heat distortion temperature of 330 f 165 c.

The general description of each mnve is shown in table 1.

Higher temperature modified novolac vinyl ester resins mnve candidates and compares them to today s premium commercially available novolac vinyl ester cnve.

More fatigue resistant than standard epoxy vinyl ester resins.

Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid.

Derakane 470 series resins are epoxy novolac based vinyl ester resins designed to provide exceptional thermal and chemical resistance properties.

We aim to replace thin film epoxies and polyurea coatings with vinyl ester resin based coatings that are.

High density cross linked products are suitable for temperatures above 250 o f 121 o c.

Vinyl esters also use peroxides e g.