Because of this vinyl esters are generally used when high durability thermal stability and extremely high corrosion resistance are a.

Vinyl ester resin uses.

In some cases conventional solvents such as xylenes are also used.

It adds excellent strength rigidity adhesion water and chemical resistance.

Mature in a reasonable time and to remain moldable long enough that it can be all used up under normal production schedules.

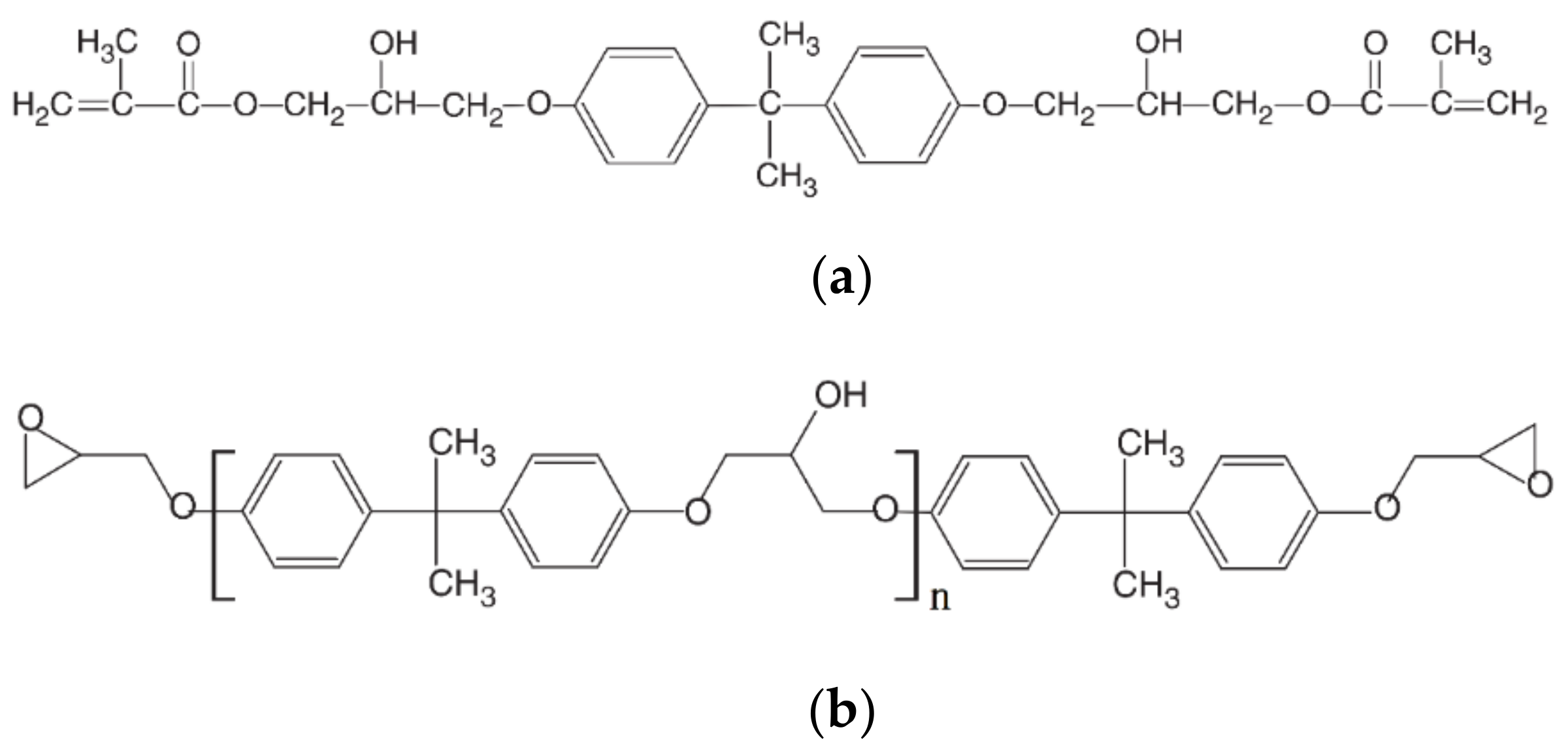

Vinylester is essentially a styrene modified epoxy resin.

Proper thickening with the usual thickening agents is an essential resin characteristic if the smc is to be ready to mold i e.

Polyester or vinyl ester resins can be used to make smc.

The diester product is then dissolved in a reactive solvent such as styrene to approximately 35 45 percent content by weight.

Their longer double bonded vinyl groups that link the ester groups together contribute a flexible nature to the resin.

Epoxy vinyl ester resins also find uses in coatings particulalry for the marine building and construction industries due to their excellent corrosion and weathering resistance.

It is typically used in boat hulls gas tanks kayaks canoes and other items that will be exposed to chemicals such as fuel or water for extended periods of time.

However most are prepared solely with reactive vinly type monmomers.

Cloth and polyester resin.

Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain.

Vinyl ester resins are a cross between polyester resins and epoxy resins.

The vinyl groups refer to these ester substituents which are prone to polymerize.

Polyester resins also known as unsaturated polyester resins upr combined with fiberglass reinforcements have been the building blocks of the composites industry for decades these formulations provide low cost ease of handling quick cure and high strength to create a wide variety of.

Vinyl ester resins vinyl esters are halfway between polyesters and epoxies as far as typical properties and toughness and they are a step up on a cost basis.

Polyester and vinyl ester resins are the most commonly used matrix resins to create composite parts.

Vinyl ester can be used as a final coat after polyester resin to create a better water barrier.

Vinyl esters also use peroxides e g.

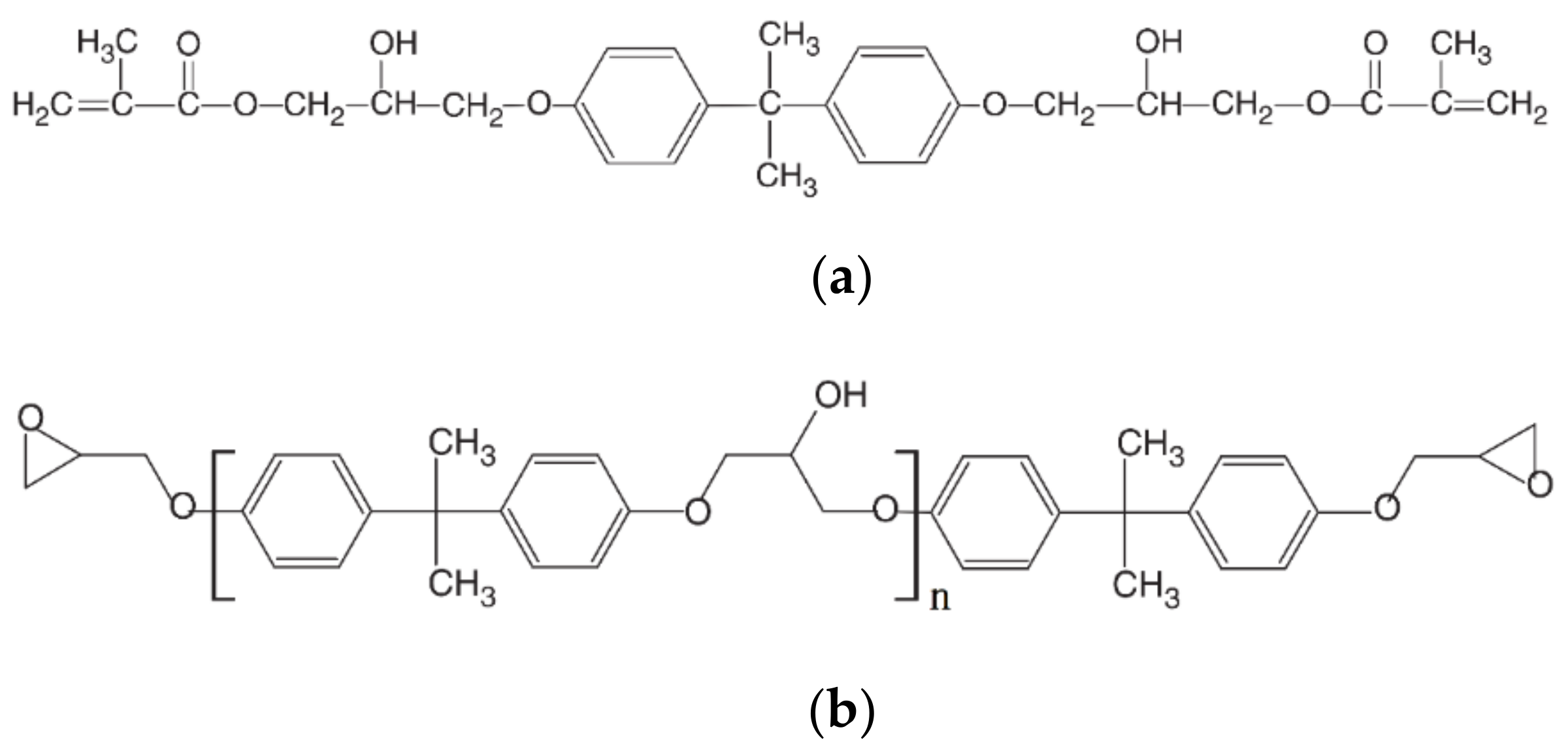

Vinyl ester resin or often just vinyl ester is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids.

Vinyl ester resins offer increased strength corrosion resistance and durability and are used in a wide variety of applications.

Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid.

Epoxy adheres to wood much better than polyester does.

While vinyl ester resins are classified as polyester based formulations they are actually an intermediate between a polyester backbone and epoxy terminations on the ends of the molecules.