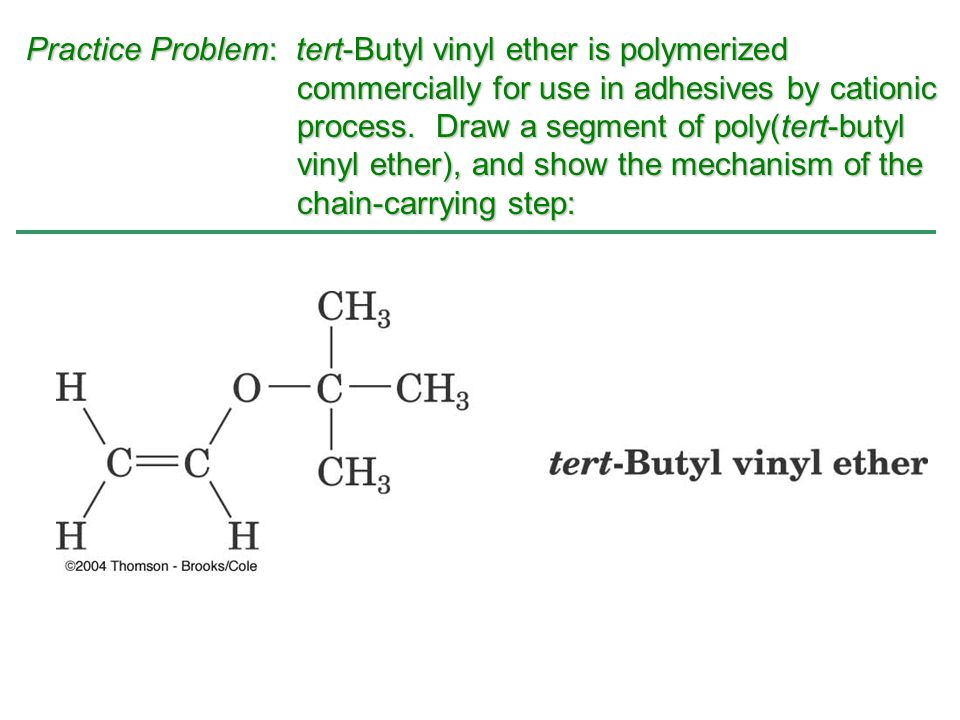

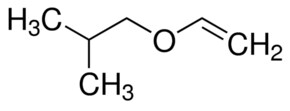

A process for efficiently producing a high purity vinyl ether represented by formula 1 from a tertiary alcohol having low reactivity is provided the process comprising reacting acetylene with the tertiary alcohol in the presence of a base using a cyclic urea compound a glyme compound or a mixture of these as a solvent.

Vinyl ether process.

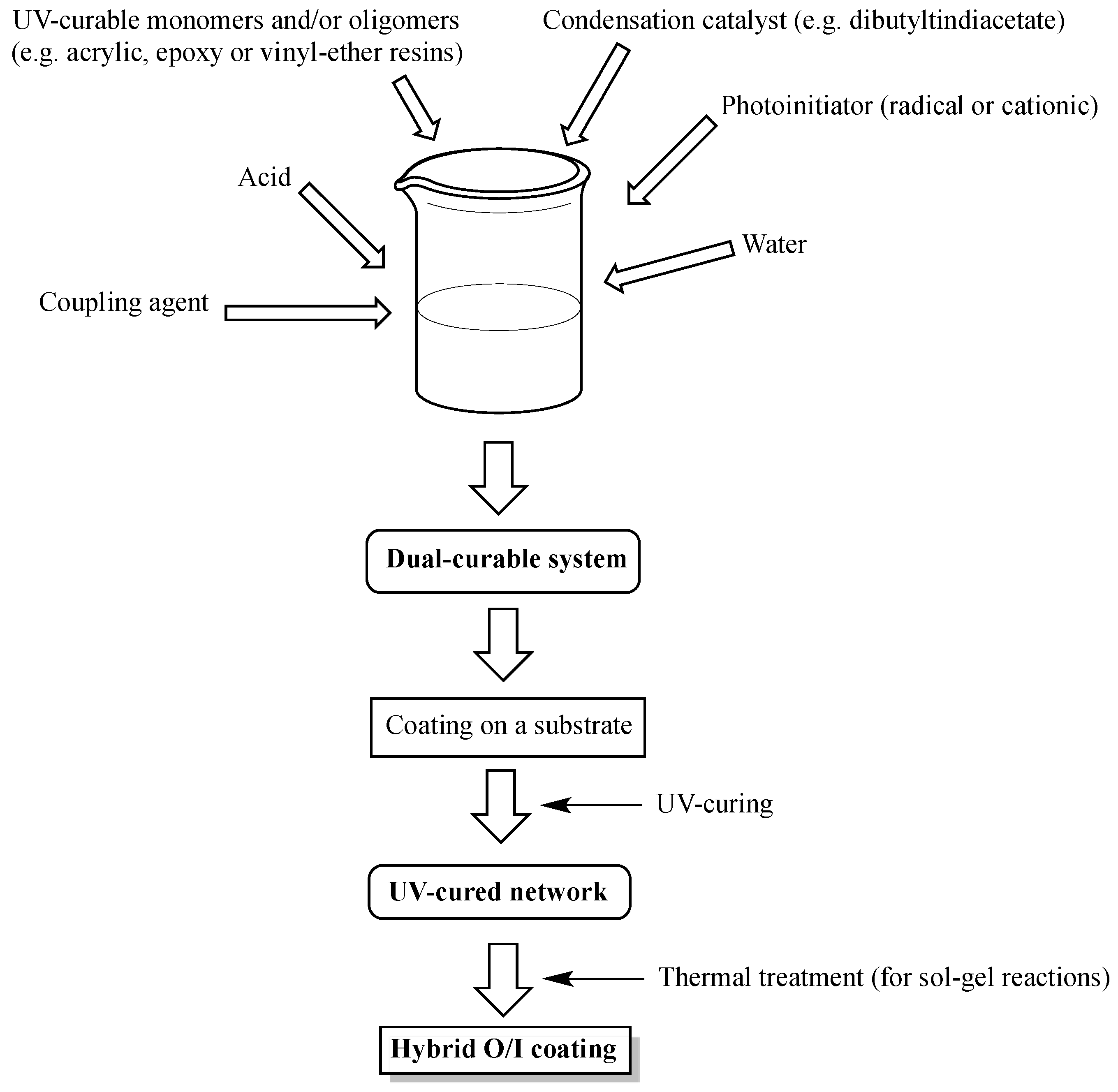

They are increasingly used in radiation curing systems because of a lower toxicity profile than the commonly used acrylic monomers.

Ethyl vinyl ether is an organic compound with the chemical formula ch 3 ch 2 och ch 2.

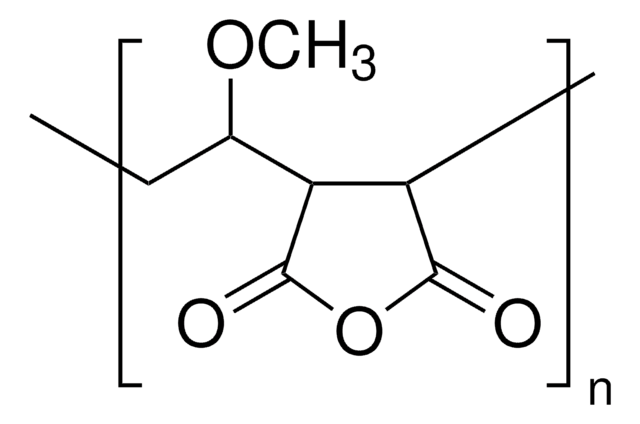

Both polymers exhibited t g s 88 and 61 c respectively well above the room temperature.

It is used as a synthetic building block and a monomer.

However this potency is hard to control with simplistic equipment.

The half life for this reaction in air is estimated to be 6 5 days 4 src.

The process involved capping the initiator tmpcl with dte in the presence of ticl 4 followed by fine tuning of the lewis acidity with the addition of ti oip 4 to match the reactivity of tert butyl vinyl ether or chve.

Vinyl methyl ether is expected to undergo hydrolysis in the environment based on hydrolysis half lives of 9 5 hours 40 days and 10 9 years at ph 5 6 and 9 respectively in structurally similar butyl vinyl ether 6.

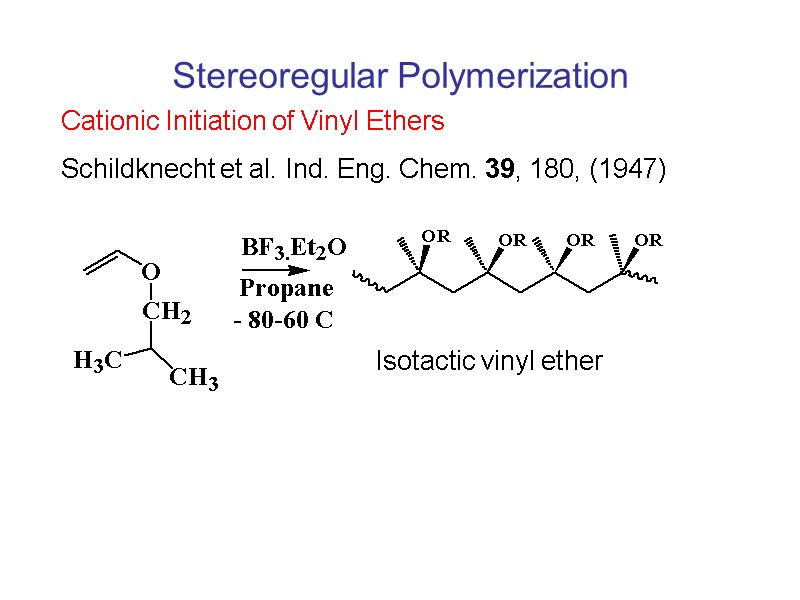

Vinyl ethers undergo homopolymerization via a cationic mechanism.

Vinyl ether is a potent anesthetic giving it a large safety margin.

The ratio of the anesthetic to lethal does for vinyl ether is 1 to 2 4 ethyl ether.

Vinyl ethers undergo radical initiated copolymerization in the presence of specific monomers such as maleates fumarates and acrylics.

Vinyl ether process ch polymer reacting prior art date 1998 09 28 legal status the legal status is an assumption and is not a legal conclusion.

Poly methyl vinyl ether alt maleic acid monoethyl ester solution1 product result match criteria.

According to a classification scheme 7 an estimated bcf of 3 src from an estimated log kow of 0 42 2 and a regression.

Many of the vinyl ethers exhibit good solvating properties and have been used as reactive diluents fo this purpose.

Direct photolysis will not be an important removal process since butyl vinyl ether does not absorb light at wavelengths 290 nm 5.

Use of ethyl vinyl ether in the synthesis of glutaraldehyde.

The use of epoxide vinyl ether combinations alleviates this problem and the presence of the vinyl ether increases the cure speed compared to a formulation in which the vinyl ether is absent 21.